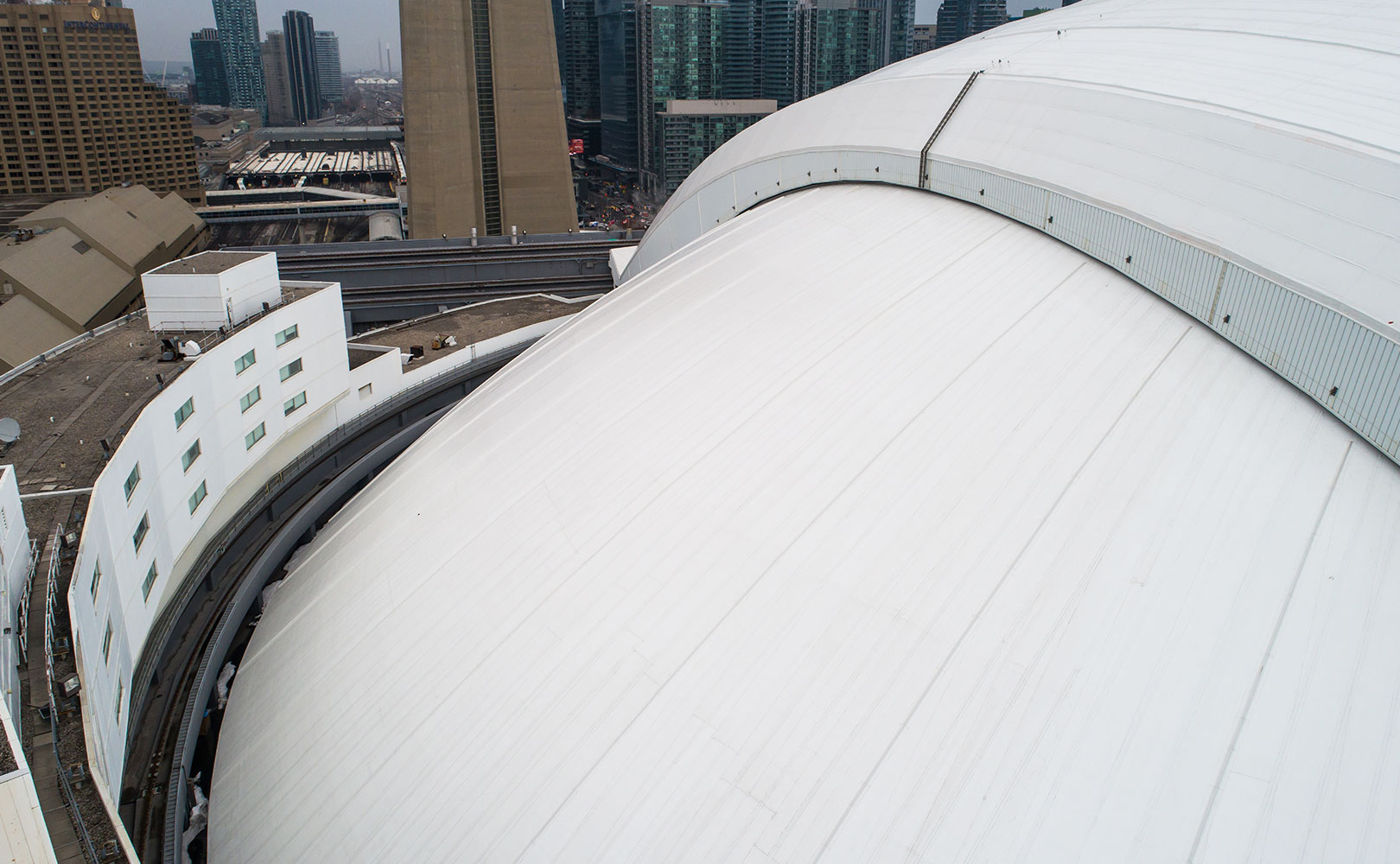

The iconic Rogers Centre got a new roof for its 30th birthday. The revolutionary retractable dome first opened in 1989.

For this project, Flynn crews had to work off swing-stages, and be tied off at all times while on the mammoth roof. The dome nature of the roof meant workers adapted to the various incline changes with custom tools and equipment. Constant communication with general contractor EllisDon and the owner was also required for site logistics, coordination with venue events, and of course the opening and closing of the roof.

As a subcontractor, Flynn was responsible for panels 3 and 4 on the roof’s north side. The crew is replacing the full system at the bottom eight inches of the roof which consists of sheet metal girts, through wall flashing and cap flashing, Sarnavap Vapour Barrier, Polyisocyanurate insulation and Sika Sarnafil PVC membrane. Sika Sarnafil 80 mil White PVC is the roofing membrane being installed. Crews began work last winter. As any roofer knows, roofing in the winter is a major challenge. The first month was not too bad, with just some frost. But then it started to snow. The gutters where our crews set up their equipment filled with snow very quickly. Because of the dome’s large surface area, even a few millimetres of snow were enough to cause many feet of snow in the gutters. Crews had to constantly dig out snow from the gutters and our snow melt systems were overwhelmed.

Total Building Envelope

Total Building Envelope