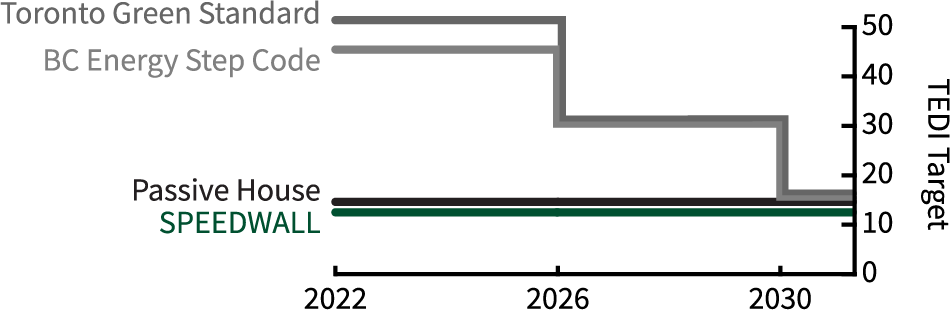

Speedwall is a factory-assembled modular exterior wall system that delivers quality and performance levels far beyond what is possible with on-site construction.

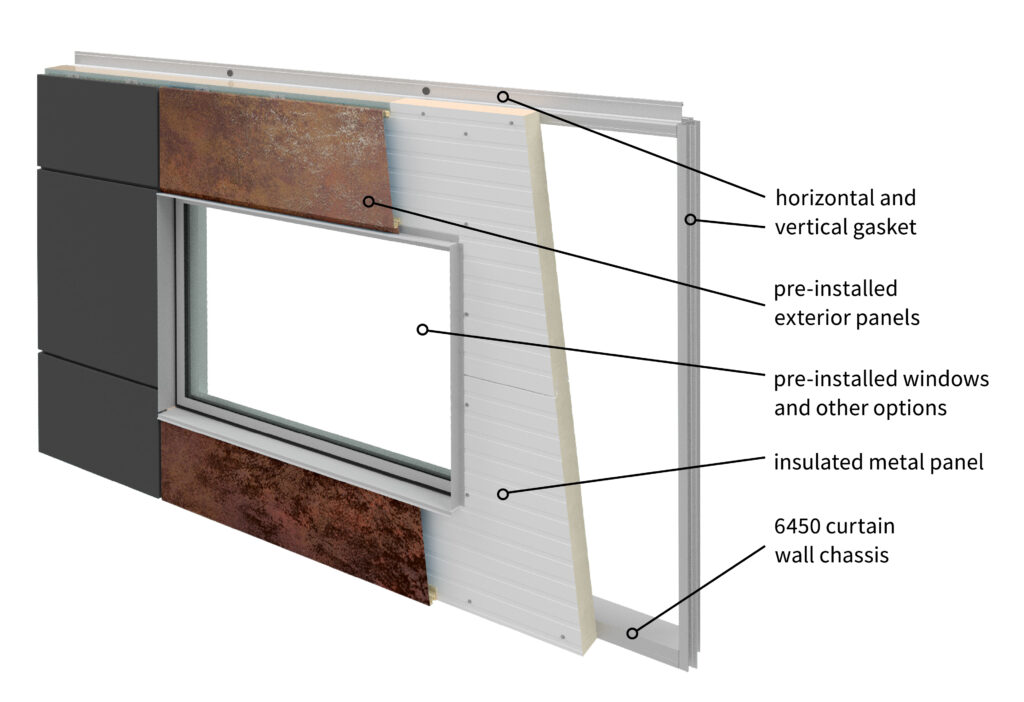

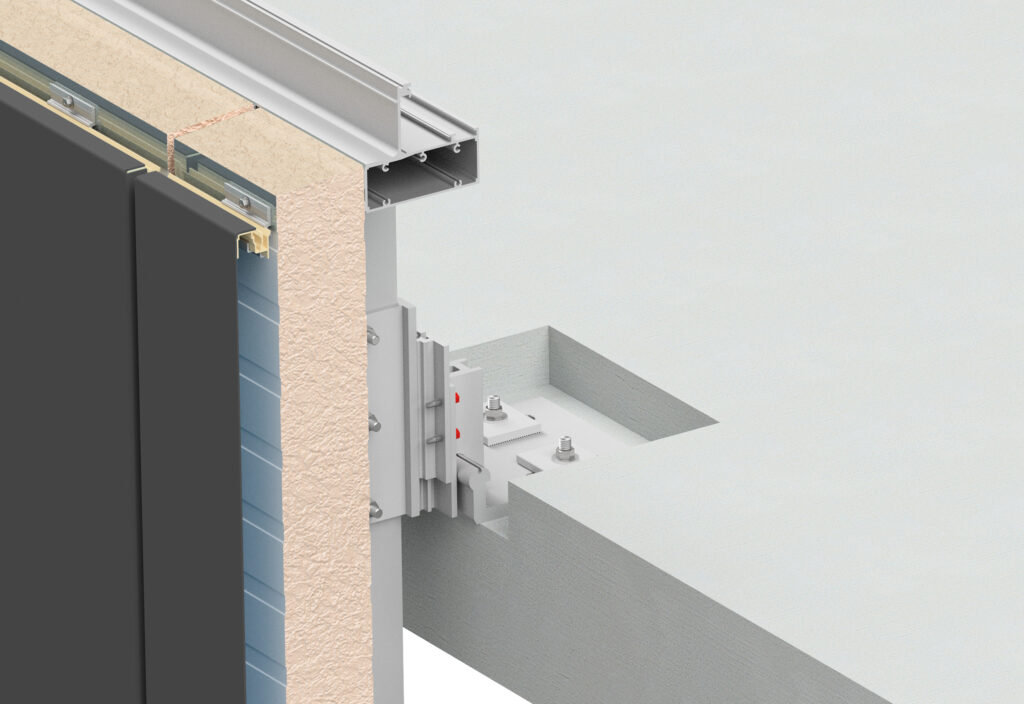

Built on an aluminum chassis based on Flynn’s 6450 unitized curtain wall system, Speedwall modules are completely self-framed, sealed, and insulated in Flynn’s manufacturing facility, with all windows, doors, and exterior cladding pre-installed.

Total Building Envelope

Total Building Envelope